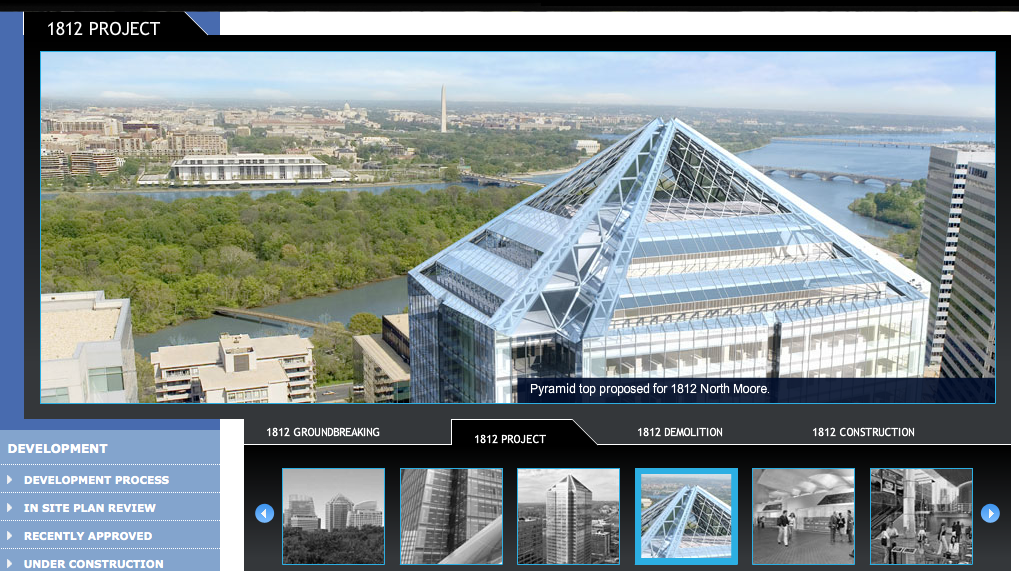

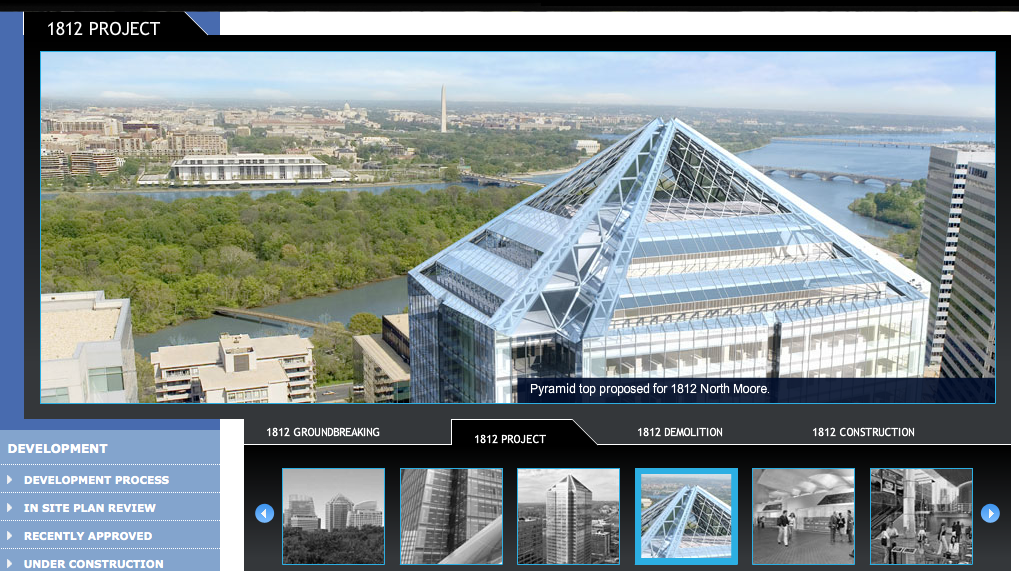

We just finished providing the strut components for the large pyramid on top of the new BIM (Building Information Modeling) office building by Davis Carter Scott Architects at 1812 North Moore Street in Rosslyn, VA. Our client is American Iron Works in Hyattsville, MD.

Bluto our Fanuc 430iW Robotic Arm with plasma torch.

Bluto in action! With cutoff rings and slot scrap piling up below.

Typically Slotted 7.5x .5 wall HSS ready for fitting. **Note* Due to the rectangular base of the Pyramid which drove the oval-under-circle geometry of the compression ring at it’s apex, in the 274 ends we cut there were 90 slot variations.

AIW Starts the next strut run

This IFC (International Function Classes) fitting is typical for the job

American Iron Works Fitters at work

100 foot long Pyramid Leg complete

Typical Pivot point for 4″ pin shown with fitting jig

Compression Ring for Pyramid’s Apex (upside down in photo)

Compression Ring detail #1

Compression Ring detail #2